Reza Hosseini, PhD – Managing Director at RadonMarket, R&D Manager & NRPP MFM Certified Radon Professional at Niton srl

Like any other measurement activity, Radon gas measurement needs a quality program to evaluate and assess the test results. A Radon quality measurement program consists of Quality Control (QC) and Quality Assurance (QA) plans. In a nutshell:

✅ The QC plans are the measures taken to increase confidence in the results.

✅ Then, the QA plans ensure that the QC plans are being done correctly and in a timely manner.

QC plans include duplicates, fields blanks, spikes, calibration, background checks, and source checks. And QA plans include creating control charts, keeping the records, and inspecting procedures. Before talking about these interesting topics 🤩, we should have a very good understanding of three concepts: PRECISION, BIAS, AND ACCURACY

Radon Measurement Quality- Precision, Bias, Accuracy

✔️ PRECISION

Consider performing multiple Radon measurements simultaneously inside a building, with the same condition and the same type of instrument. After comparing their results, the measurement is Precise if the results are close together. On the other hand, if the results are far away from each other, the measurement has poor precision.

Measurement precision should be controlled as part of the Radon QC plans. An example of this control is to perform “Duplicates📣. “

| 📣 Duplicates are two simultaneous measurements with the same device. The number of them should be equal to 10% of measured locations (per device type) and for a maximum of 50 duplicates per month. |

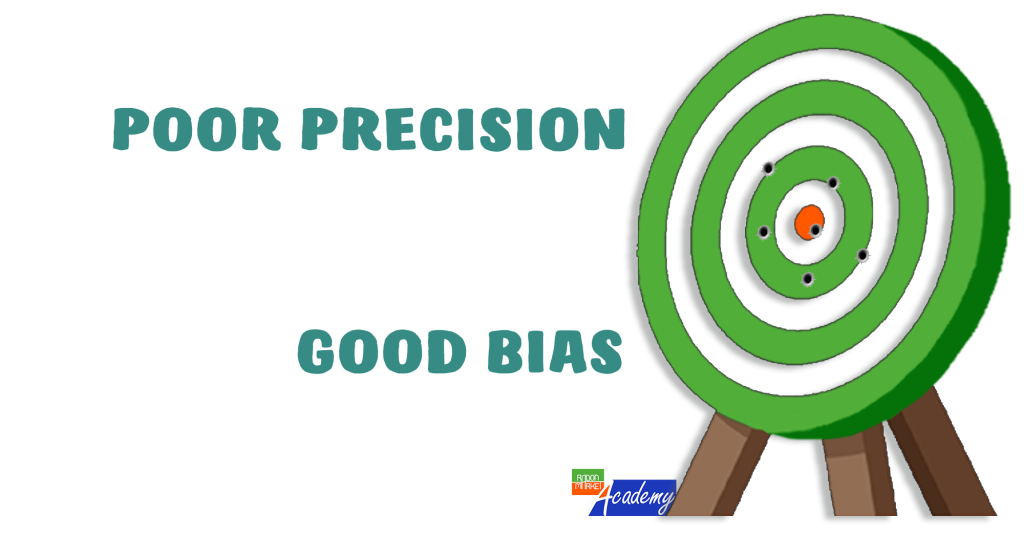

Now let’s see why having good Precision is essential but not enough. When testing a building for Radon, the Radon level of the building is unknown. Therefore even if the multiple results are close together (good Precision), they could be far from the actual Radon concentration or the target level. In other words, there could be good Precision but poor “Bias.”

Radon Measurement Quality, Precise measurement with poor Bias

✔️ BIAS

The Bias could be associated with improperly storing the detectors or due to collecting Radon by detectors during their shipment, or it could even be a laboratory problem🔔.

| 🔔 Bias in Radon measurement is typically on a positive side, and it indicates higher Radon levels compare to the actual values. |

Bias shows how far the result is from the target value. But how is it possible to determine the Bias when the target value is unknown? The solution is to define a known target value equal to zero! It is achievable by measuring the Radon concentration from not exposed detectors and calculating how much the results are off from zero. This way of calculating the Bias in the Radon QC plans is called “Field blanks📣.”

| 📣 Field blanks are not exposed but evaluated devices. The number of them should be equal to 5% of the measured locations (per device type) and for a maximum number of 25 field blanks per month. The results should be close to 0 Bq/m3. |

Having a good bias does not indicate that the measurement is precise too. Here is where “Accuracy” comes into the scene. An accurate measurement is Precise with good Bias.

Radon Measurement Quality, not Precise measurement with good Bias

✔️ ACCURACY

Accuracy is mainly a function of Bias (how far the measurement results are from the target value). The only way to verify the Accuracy is by exposing some sample detectors to a known Radon environment. These sample detectors are called “Spikes📣,” and they should be part of the QC plans. Spike samples are sent to a Radon chamber (it could be a secondary Radon chamber) and exposed to predefined Radon concentration. Then the sample’s measured values are compared with the Radon chamber declared concentration to determine the measurement’s Accuracy.

| 📣 Spikes are devices exposed to known Radon environment. The number of spike samples should be equal to 3% of the measured locations (per device type) and for a maximum of 6 per month and a minimum of 3 spikes per year. |

Radon Measurement Quality, Precise measurement with good Bias, Accurate measurement

By understanding these three essential concepts, we are now able to go into detail and talk about Quality Controls (QC) and Quality Assurance (QA) plans. So do not miss the future numbers of RadonMarket Magazine.